Fusing

Fusing machines

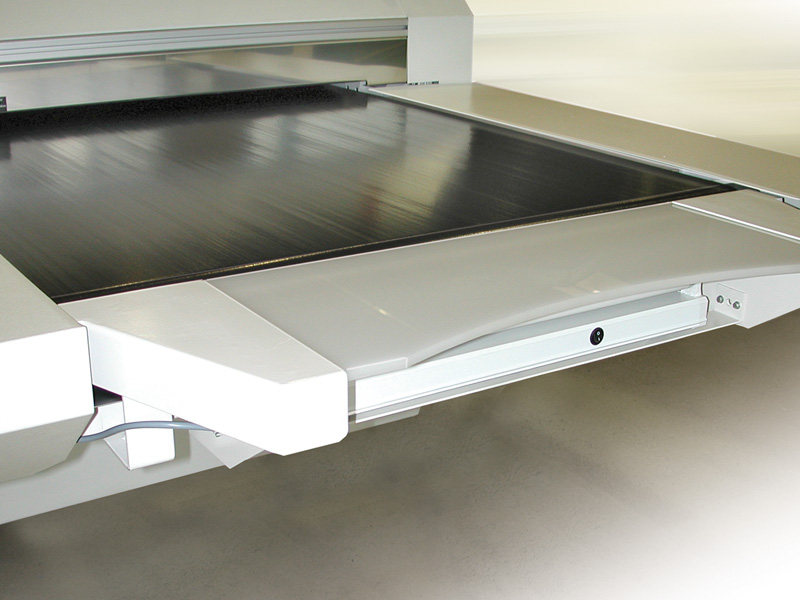

Fusing Machine | continuous

Comfort solution with intelligent control

This system designed for efficiency offers, in addition to comfortable operation for conducive working and effective workflow, the latest generation of controls.

Heating modules with three registers and two control zones configured in terms of optimum energy efficiency maintain the temperature within the processing window, even under maximum load. Silicone coated pressure rollers with large diameters and separate deflection rollers keep the pressure constant over the complete belt width.

The latest innovative SIEMENS comfort control stands for simple and intuitive operation by means of a large 7“ touch screen.

Technical data

Fusing width (mm) | 1,000 | 1,400 | 1,800 |

Dimensions L x W x H (mm) | 4,105 x 1,580 x 1,250 | 4,105 x 1,980 x 1,250 | 4,105 x 2,380 x 1,250 |

Pressure (N/cm2) | 0 to 50 | 0 to 35 | 0 to 18 |

Speed (m/min.) | 1 to 12 | 1 to 12 | 1 to 12 |

Control zones | 2 | 2 | 2 |

Temperature max. (°C) | 200 | 200 | 200 |

Heating power approx. (kW) | 18.2 | 23.4 | 31.2 |

Length of heating zone (mm) | 1,275 | 1,275 | 1,275 |

Connected load approx. (kW) | 19 | 24.5 | 32.2 |

Voltage (volt) | 400 | 400 | 400 |

Weight (kg) | 1,200 | 1,400 | 1,600 |

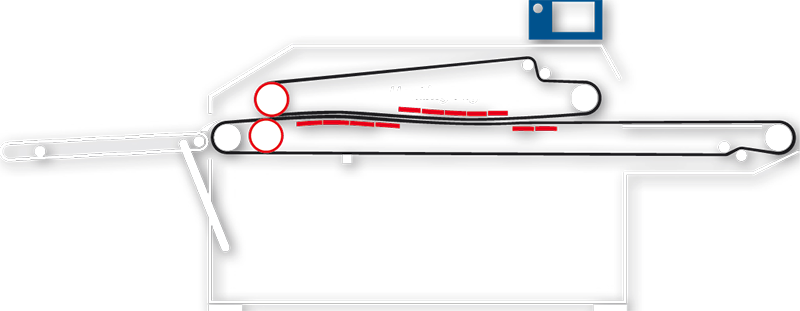

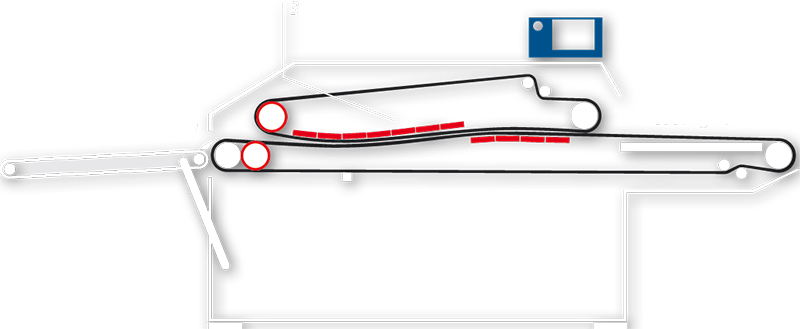

Fusing Machine | continuous

The sensitive solution for leather applications

The system, solution oriented to the special tasks in processing leather and leather blanks, preserves this sensitive material through an intelligent temperature control. Heating areas are optimized such that only a short heating zone heats the leather minimally from the bottom preventing the leather surface from damage.

Our pressure rollers, with precise gap settings especially designed for thicker foams and new three-dimensional knitted fabric for leather lamination, avoid a too powerful pressing of the three-dimensional material to prevent damage.

A section of the loading belt is equipped with cooling elements and can be connected to an external chiller keeping the once set temperature safe and constant.

Technical data

Fusing width (mm) | 1,000 | 1,400 | 1,800 |

Dimensions L x W x H (mm) | 4,105 x 1,580 x 1,250 | 4,105 x 1,980 x 1,250 | 4,105 x 2,380 x 1,250 |

Pressure (N/cm2) | 0 to 50 | 0 to 35 | 0 to 18 |

Speed (m/min) | 1 to 12 | 1 to 12 | 1 to 12 |

Control zones | 3 | 3 | 3 |

Temperature max. (°C) | 200 | 200 | 200 |

Heating power approx. (kW) | 18.2 | 23.4 | 31.5 |

Length of heating zone (mm) | 1,275 | 1,275 | 1,275 |

Connected load approx. (kW) | 18.5 | 23.5 | 32 |

Voltage (volt) | 400 | 400 | 400 |

Weight (kg) | 1,200 | 1,400 | 1,600 |

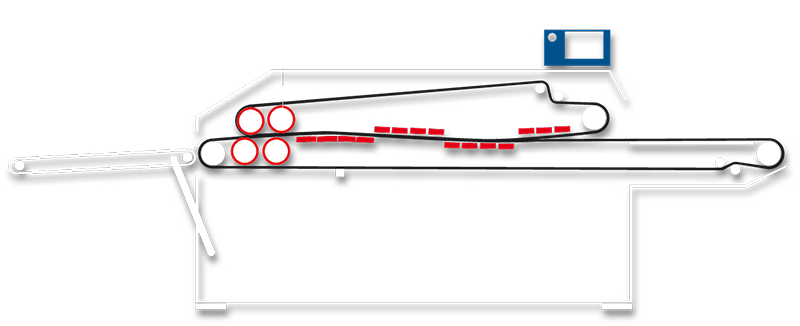

Fusing Machine | continuous

Perfected heating power for more efficiency

The RPS series is completed by this model with an extended heating system and higher heating power. Thus a total of four registers and four control zones are available to meet demanding fusing applications with top quality.

In combination with our own development of a 3D heating system, you achieve optimum quality and efficiency in fusing.

12 zones 3D heating system

Working on three lanes simultaneously with different temperatures allows the possibility of fusing openly or sandwich. For each lane, the temperature profile can be controlled via 4 separately controllable zones. Thus, a total of 12 SPS controllable zones are achieved.

Technical data

Fusing width (mm) | 1,000 | 1,400 | 1,800 |

Dimensions L x W x H (mm) | 4,275 x 1,580 x 1,250 | 4,275 x 1,980 x 1,250 | 4,275 x 2,380 x 1,250 |

Pressure (N/cm2) | 0 to 50 | 0 to 35 | 0 to 18 |

Speed (m/min.) | 1 to 12 | 1 to 12 | 1 to 12 |

3D heating system (zones) | - | 12 | 12 |

Control zones | 4 | 4 | 4 |

Temperature max. (°C) | 200 | 200 | 200 |

Heating power (kW) | 23.1 | 29.7 | 39.6 |

Length of heating zone (mm) | 1,635 | 1,635 | 1,635 |

Connected load approx. (kW) | 24 | 30 | 40 |

Voltage (volt) | 400 | 400 | 400 |

Weight (kg) | 1,500 | 1,700 | 2,000 |

Fusing Machine | discontinuous

Modular solutions for standardized tasks

The APM is a compact automatic press which offers universal applications for tailoring and styling departments. It is especially suitable for fusing and flock-coating of textile materials.

Technical data

Press area (mm) | 500 x 400 | 1,000 x 400 | 800 x 500 | 1,100 x 500 |

Pressure (N/cm2) | 0 to 7 | 0 to 3.5 | 0 to 3.3 | 0 to 2.5 |

Power consumption (kW) | 2 | 3.5 | 3.8 | 5 |

Voltage (volt) | 230 | 230 | 400 | 400 |

Weight (kg) | 145 | 170 | 180 | 220 |

Fixierpresse | discontinuous

Modular solutions for standardized tasks

This compact vertical pneumatic press can be used as a laboratory or transfer printing press and can be individually configured as a cooling press, heating press, or molding press with special tool fixing device.

Technical data

Press area (mm) | 250 x 250 | 350 x 300 |

Press force standard at 8 bar air (kN) | 3.5 | 3.5 |

Standard cylinder diameter (mm) | 80 | 80 |

Stroke (mm) | 160 | 160 |

Fusing Machine | discontinuous

Modular solutions for standardized tasks

Fusing press with modular extendable loading tray, bridge-type construction for high pressures.

Technical data

Press area (mm) | 1,200 x 600 | 1,200 x 800 | 1,300 x 700 | 1,300 x 800 | 1,400 x 700 | 1,400 x 800 | 1,600 x 700 |

Pressure (N/cm2) | 0 to 9 | 0 to 7 | 0 to 7 | 0 to 6 | 0 to 7 | 0 to 6 | 0 to 6 |

Press force approx. (t) | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

Connected load approx. (kW) | 19 | 24 | 22 | 25 | 24 | 25 | 27 |

Heating power approx. (kW) | 16 | 21 | 20 | 23 | 22 | 23 | 25 |

Stroke (mm) | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

Temperature max. (°C) | 220 | 220 | 220 | 220 | 220 | 220 | 220 |