Thermostamping

Stamping Molding

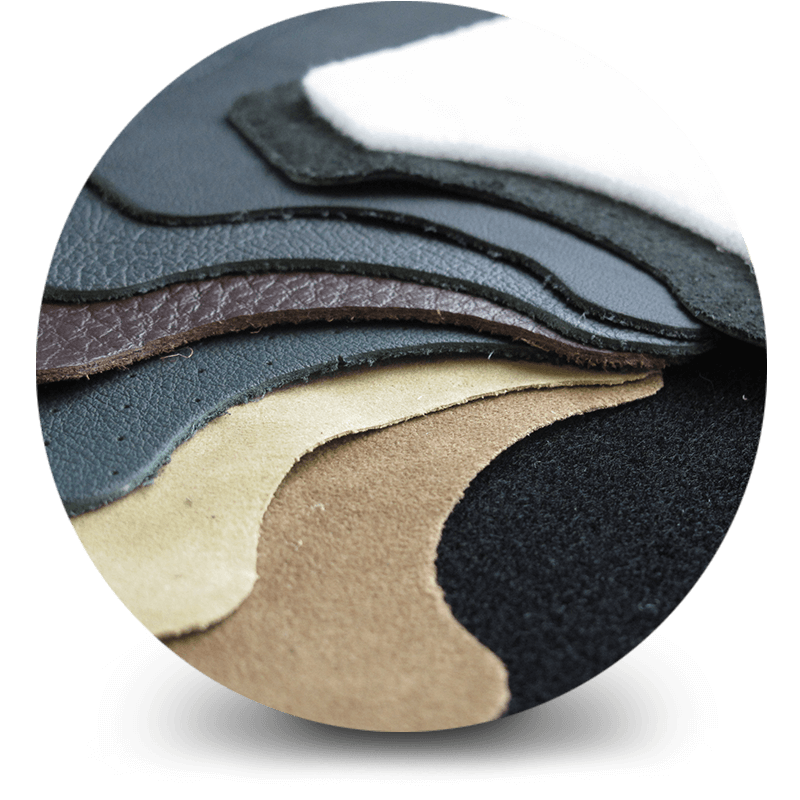

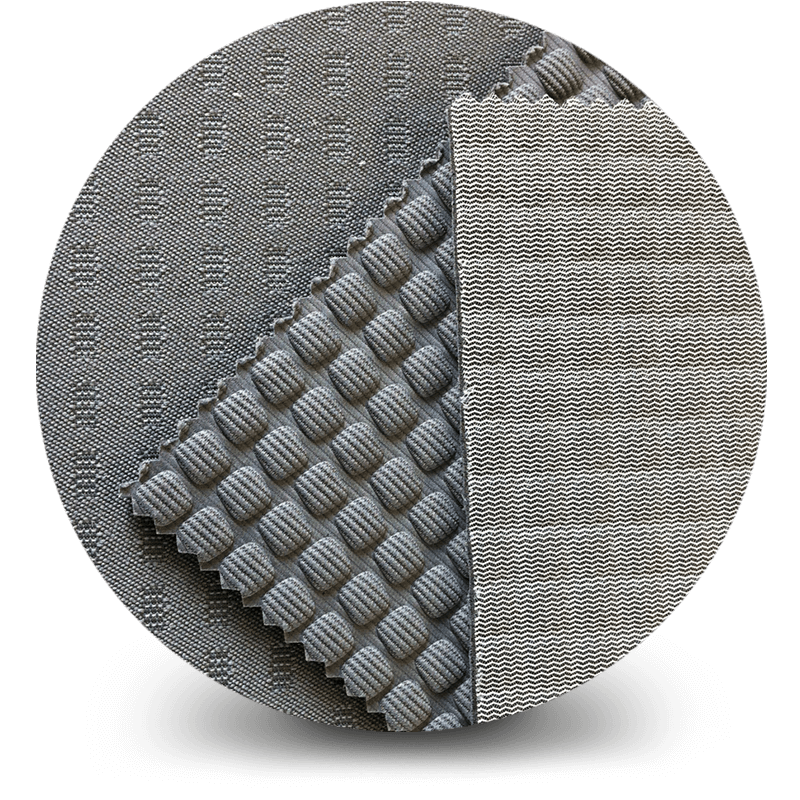

Thermostamping presses are heating presses for stamping and punching of thermo-formable foams with special tools. Typical applications are engine compartment insulations and seat covers. Also automotive interior fabrics can have contours stamped into the material thus giving the textiles an interesting optic. Meyer offers different press concepts depending on requirements. Plate size, stroke and press force are adapted to the respective project. Furthermore we also offer solutions for a production with blanks as well as from roll to roll.

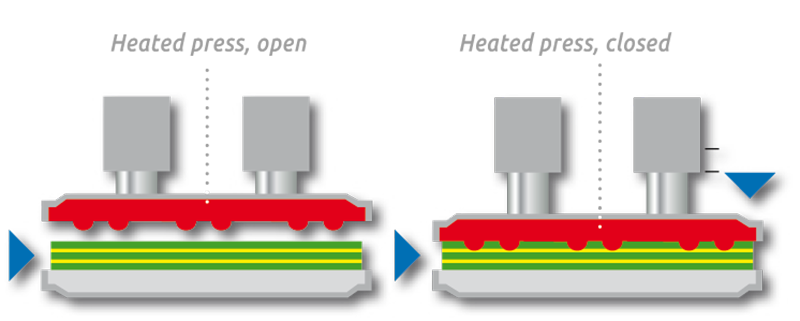

Functionality

In contrast to thermomolding a hot tool is used for thermostamping. In the stamping area inside the press the material is so strongly thermally stressed that is does no longer have any rebounding force. This is the only way to ensure that the stamping pattern is permanent. This method uses short lift strokes to stamp patterns and contours into the materials.

Specifics

The big advantage of the thermostamping process is stamping and punching in one step while the punched edge is heat-sealed. Thus further edge processing is not necessary. In connection with a cooling press also parts for aviation industry can be stamped using a stepped tool. The thermostamping machines do have the machine classification AHV-BT.