Fusing

Proven Reliable

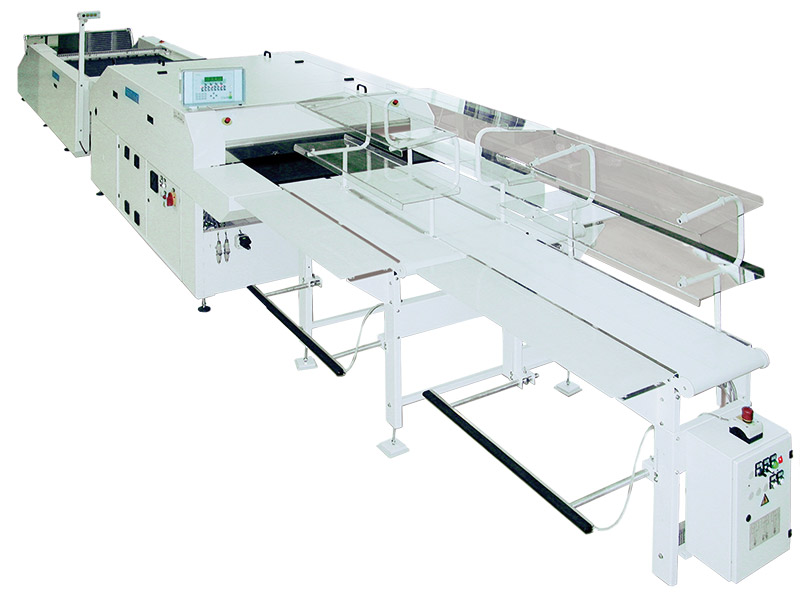

Meyer is one of the leading manufacturers for fusing machines used in the garment industry. In the sector of continuous fusing machines, Meyer offers the suitable machine for every application at different widths. Stacker and loading belts make this large selection complete. Numerous options enable an optimal adaptation to customers‘ requirements.

Functionality

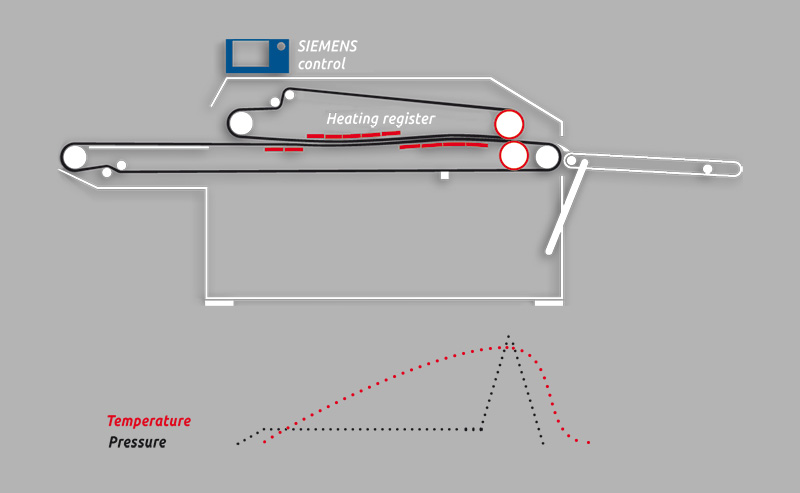

Fusing is a classic application in the clothing industry for sticking together two cloths. It is also used in the automotive and furniture industry for applying foams, knitted spacer or nonwovens to leather. A thermoplastic adhesive located between two flexible cloths is melted and the compound is fused by means of two pressure rollers at the end of the machine. Fusing - in contrast to laminating - does not use cooling. This means there always has to be a bonding. Coating is not possible. Furthermore due to the concave-convex heating only flexible and thin material can be processed.

Specifics

Meyer fusing machines can be designed with various modules and features. Our in-house developed options increase safety and profitability while relieving the operator as much as possible.

We offer the following modules and features:

- Loading belts

- Return belts

- Extension of loading area with hinged side flaps

- Trays

- Light table

- Stacker systems

- Double pressure rollers

- Multiflex rollers

- Waistband winder

- Barcode Scanner/ Printer