Laminating

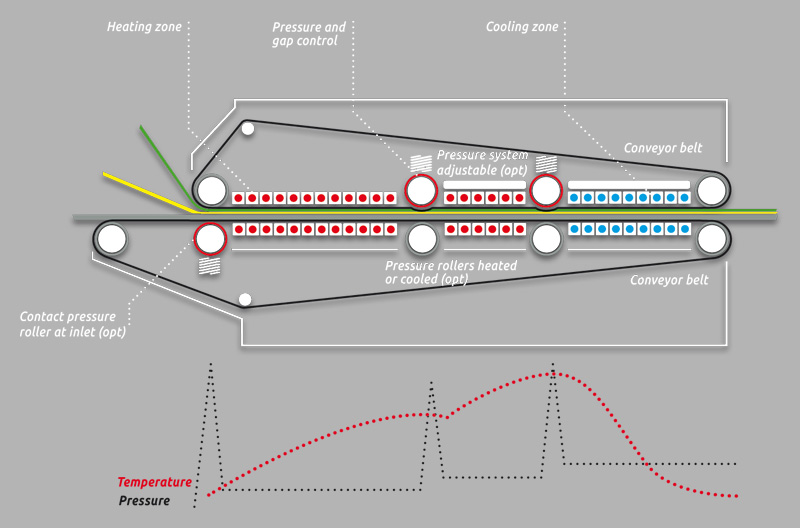

Temperature Pressure

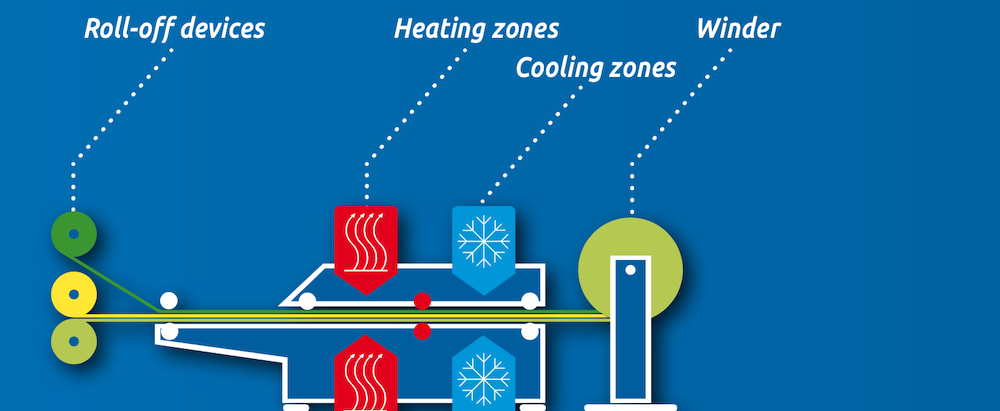

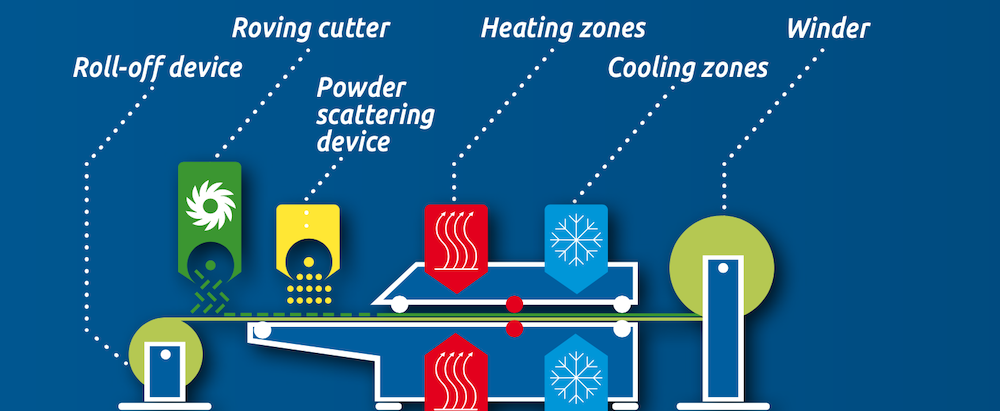

The laminating machines from Meyer enables a multiplicity of applications. Possible areas of application include foil and powder coating, calibrating, thermofixing and surface consolidation. As a machine building company with decades of experience we provide you with solutions in the field of Flatbed laminating lines which are individually adapted to your requirements. With our in-house developed modules and optional features we are able to configure optimal and economical production lines together with our customers.

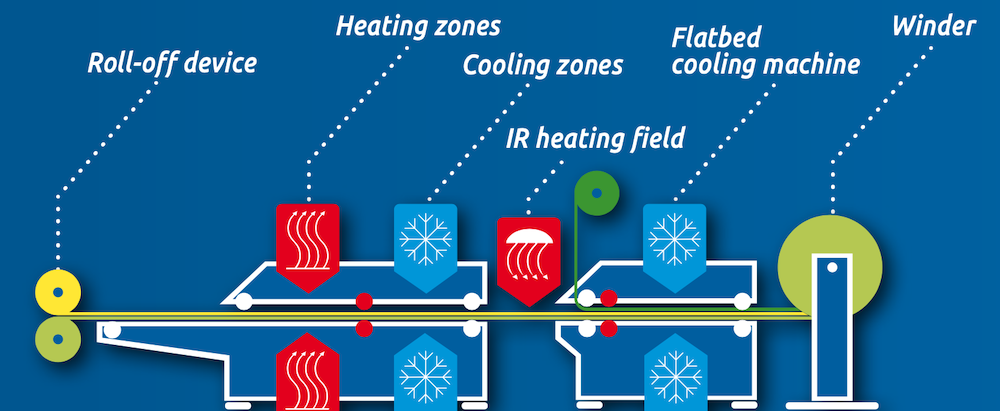

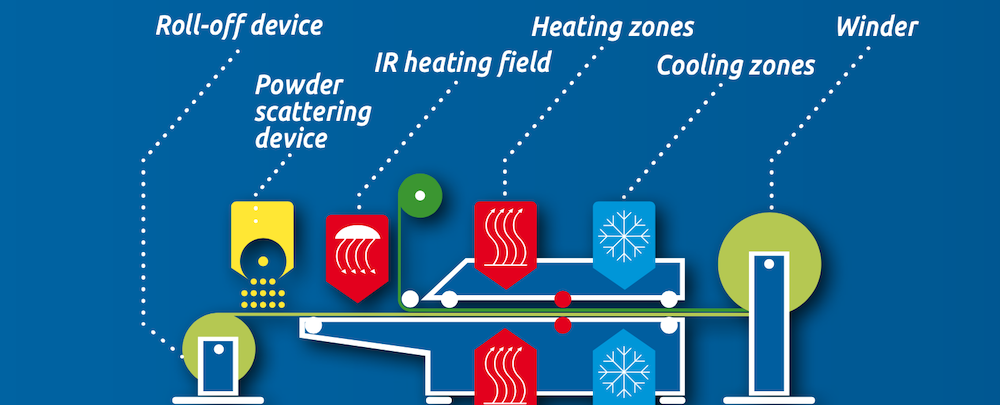

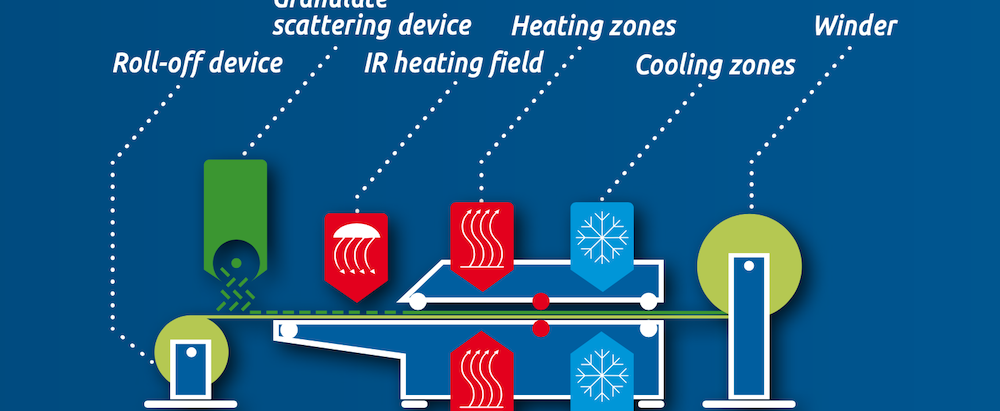

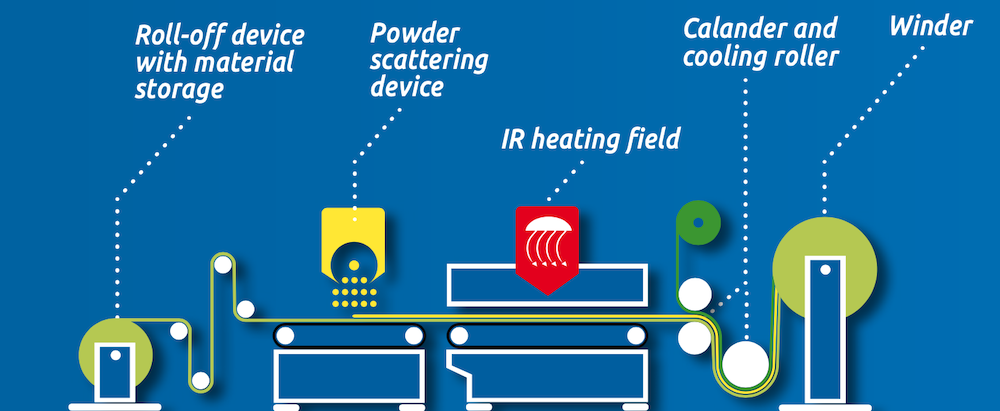

Functionality flatbed-laminating

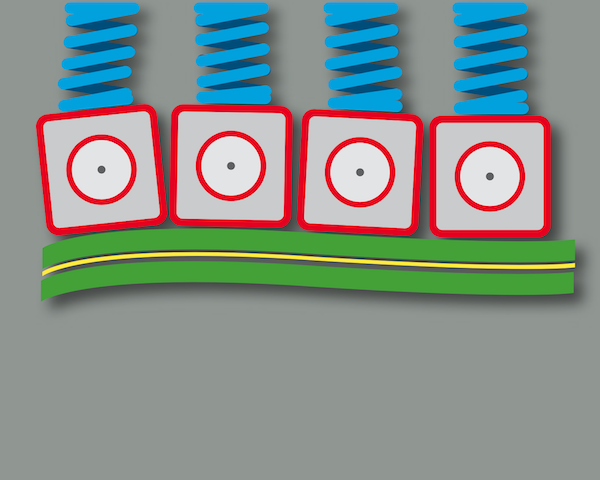

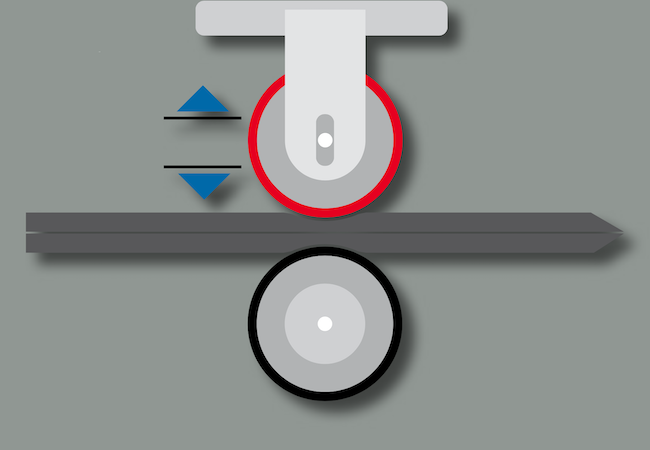

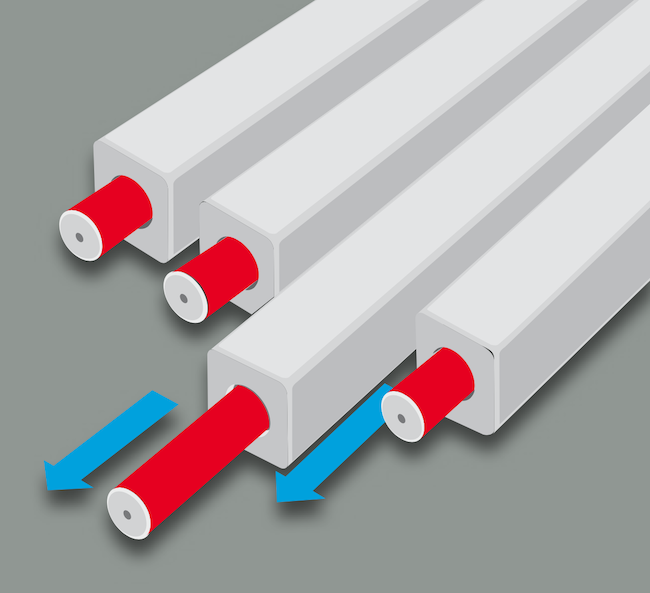

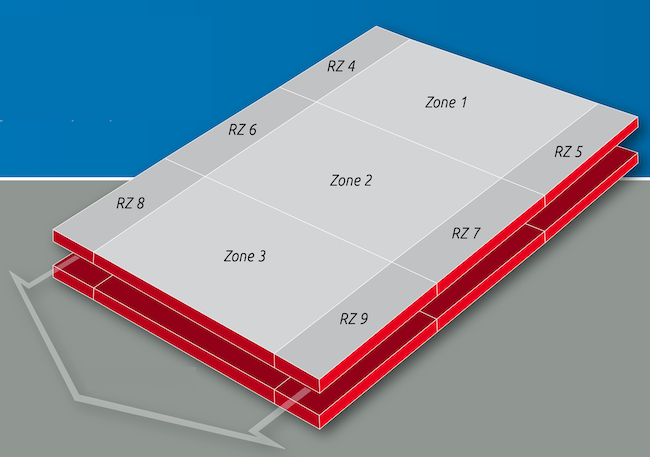

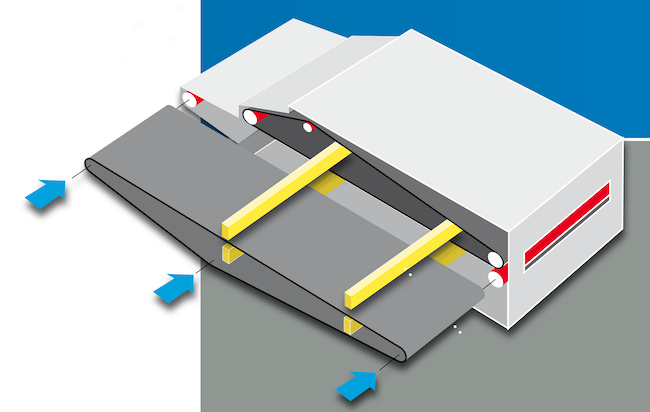

Meyer’s flatbed laminator systems are double belt presses with integrated contact heating and cooling. The materials that are laminated are heated very gentle. Due to the long heating zone the materials are laminated perfectly with high bonding strength. Right after the heating the materials can be pressed together or calibrated to a set thickness with the pressure rollers. To stabilize this compound the materials a cooled down before they exit the double belt press. With the flat gap between the belts and the precise height adjustment even rigid plates with a thickness of up to 150mm can be laminated.

With our lamination system solutions, we normally use thermoplastic adhesives as they provide a simple, environmentally friendly and, for almost any application, usable solution. In addition to environmental and health aspects, recyclability, purity of variety or fogging become an important matter. Depending on the individualized specifications, alternative adhesive systems such as reactive adhesive can be run with our machines.