Scattering

Scattering machines

Powder scatter

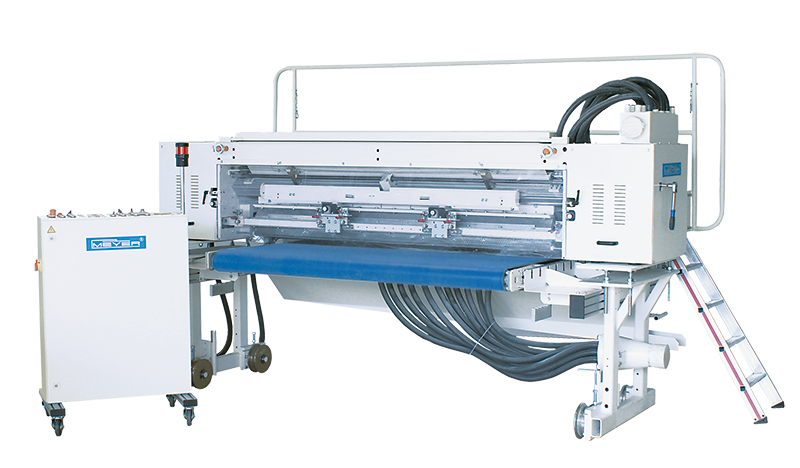

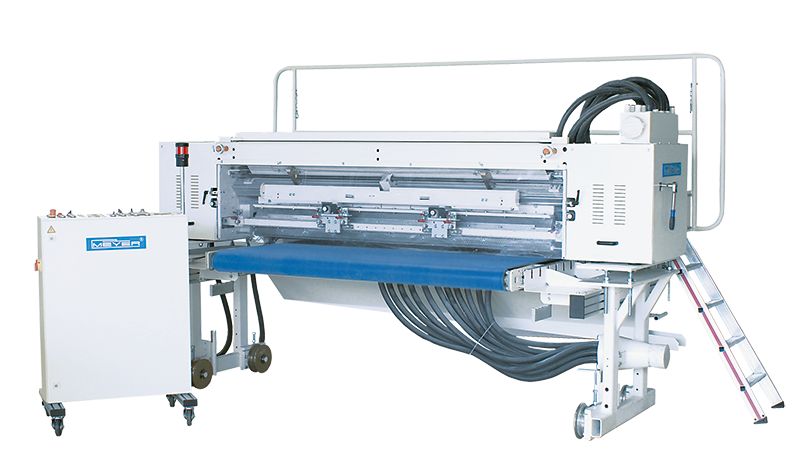

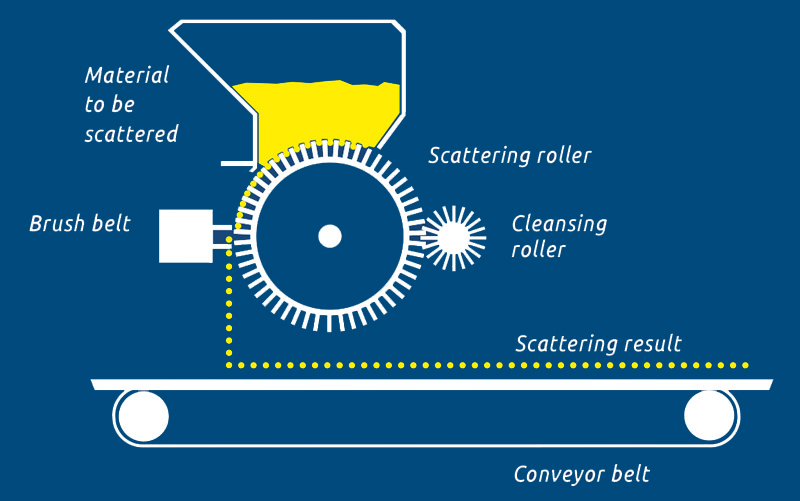

For even and homogeneous distribution

A scattering roller coated with a special needle covering in connection with a precisely adjustable brush belt provide for high-precision and very even application of the material to be scattered. This scattering system allows an infinitely adjustable working width between 50 mm and 5,000 mm as well as the possibility to choose application weights between 3 g/m2 and 2.000 g/m2. Our user-friendly scattering systems enables an exchange time for scattering roller or brush belt less than 5 minutes in case of maintenance or process changeover. The scattering accuracy depends on the used material to be scattered and is as follows for an applied quantity of <25 g/m2 at ± 2 g/m2 resp. >25 g/m2 at ± 5%. Furthermore it is possible to archive specified weights as recipes and to store them in real time for process monitoring.

We offer scattering units for powdery materials such as

- Thermoplastic adhesives

- Epoxy powders

- Recyclers

- Activated carbon

- Filling material

- Sand

- Grains

We developed a further type of scattering machines for smaller sizes as well as for manageable volumes and laboratory applications. Our small powder scatter can either be used integrated into a whole line or as stand-alone version.

Technical data

Width (mm) | 700 to 5,000 | 400 or 600 (small system solution) |

Scattering roller Ø (mm) | 130 or 225 | 90 |

Brush unit | oscillating or rotating | oscillating or rotating |

Filling | manual or automatic | manual or automatic |

Scattering width | infinitely adjustable | infinitely adjustable |

Scattering quantity | infinitely adjustable, synchronous with line speed | infinitely adjustable, synchronous with line speed |

Granule scatter

For everything except powder – individual and innovative

In principle, for granule scattering a distinction is made between two different possibilities – fiber materials or granules. Granules are being processed in a way similar to scattering powder. But for scattering granules the choice of needle covering is important. The needle covering has to be adapted to the granule in particular. Once the granule is inside the needle covering it is being removed out of the needle covering by means of a rotation controlled brush. For fiber material the material to be scattered is loosened in a winding tower by means of piker rollers and then conveyed to the scattering roller. By means of a counter-rotating brush the fiber material is distributed onto the material lane. For both methods the feasibility has to be checked. Therefore our text center is available for you.

Technical data

Width (mm) | 700 to 5,000 | 400 or 600 (small system solution) |

Brush unit | oscillating or rotating | oscillating or rotating |

Filling | manual or automatic | manual or automatic |

Scattering width | infinitely adjustable | infinitely adjustable |

Scattering quantity | infinitely adjustable, synchronous with line speed | infinitely adjustable, synchronous with line speed |

Scattering Machine

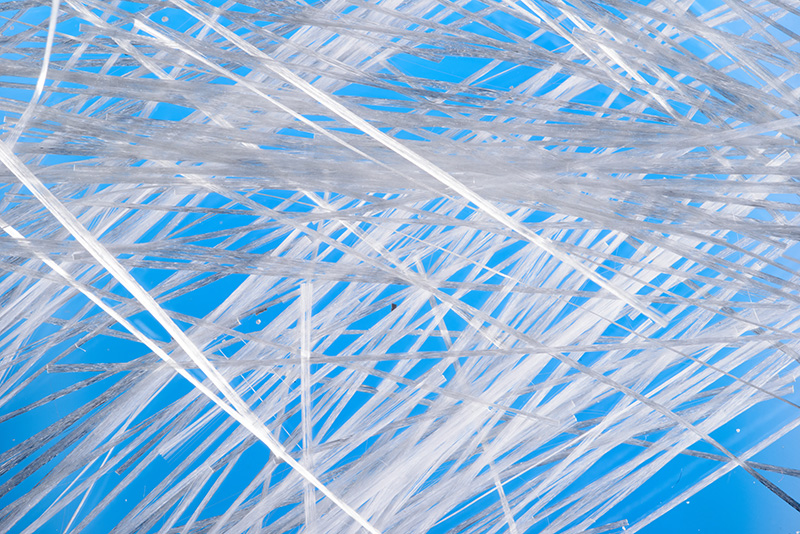

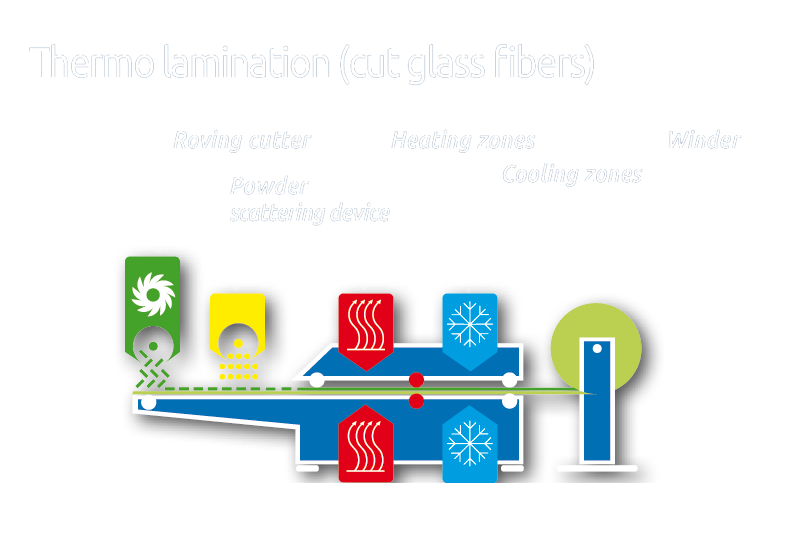

Flexible production line for glass mats

This innovative line concept for glass mat production from glass rovings consists of a cutting unit which cuts the glass fiber rovings to a defined length and then spreads them evenly onto a conveyor belt. Subsequently, a powder scatter distributes an adhesive powder onto the loose fibers. The actual mat itself is then produced inside the laminating machine. In order to increase production speeds an infrared pre-heating station is available so that the adhesive powder can melt faster. Worldwide our satisfied customers trust in our technically mature solution for glass mat production.

Technical data

Width (mm) | 700 to 2300 |

Roving feed | up to 84 |

Roving cut length | 2 inch |

Mat weigth | approx. 100g/qm |

Production speeds | up to approx. 25 m/min, depending on mat weight and thermoplast |

Scattering quantity adhesive powder | typically from 8 -30 g/qm depending on requirements |

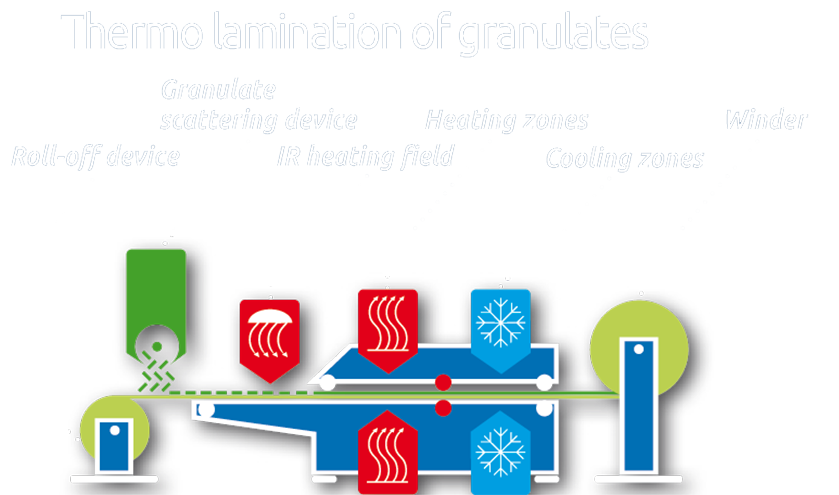

Coating line

Online and offline – but always highly accurate

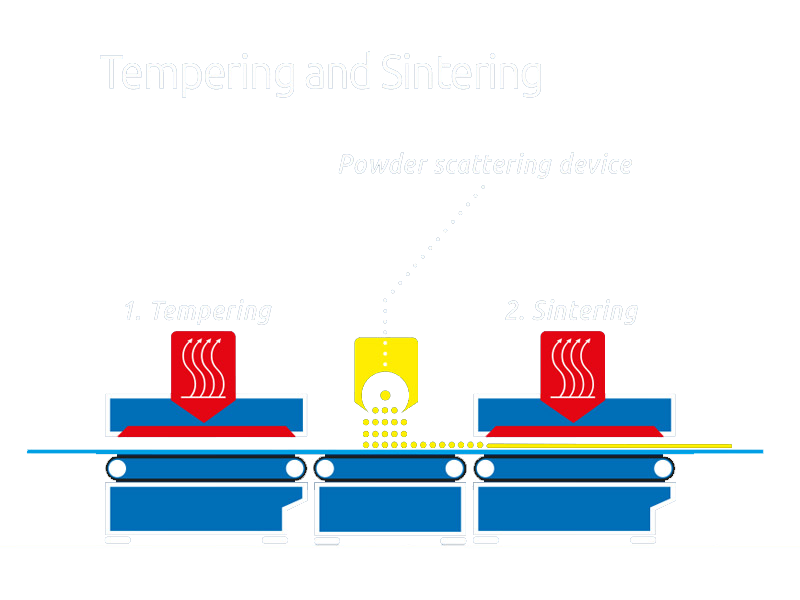

To stabilize fiber materials a small amount of thermoplastic adhesives or epoxy resins is applied onto the material lane by means of a powder scatter and afterwards fixed to the material lane by means of a contact-free heat treatment (for examples by means of a infrared heating field). Here the right melting degree and a high-precision powder application is decisive for the further steps to take place in a process-safe manner. During the online process the powder is applied contemporaneous to the production of the fiber layer. Offline processes the material from roll to roll.

Technical data

Width (mm) | up to 5,000 |

Scattering roller Ø (mm) | 225 |

Brush unit | oscillating or rotating |

Filling | manual or automatic |

Scattering width | infinitely adjustable |

Scattering quantity | infinitely adjustable, synchronous with line speed |

Temperature | up to 300°C |