Laminating

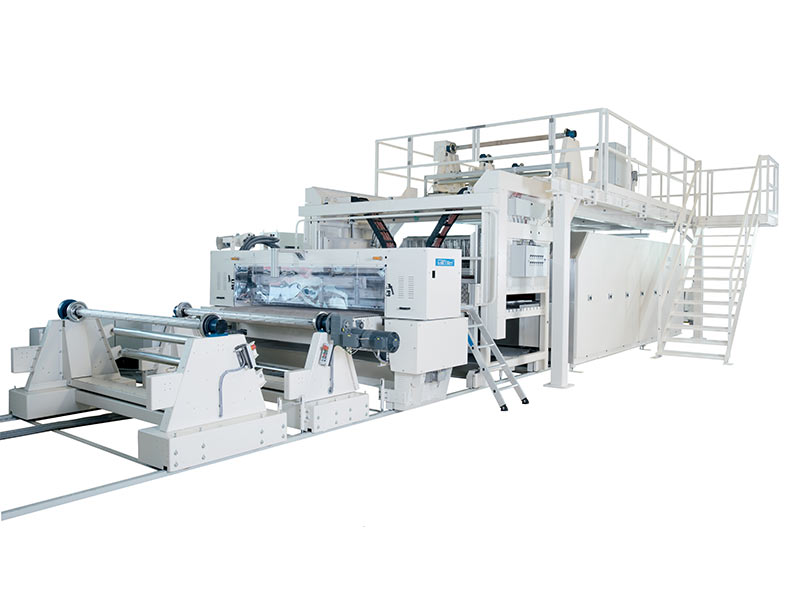

Laminating machines

Flatbed laminating machine | Flatbed

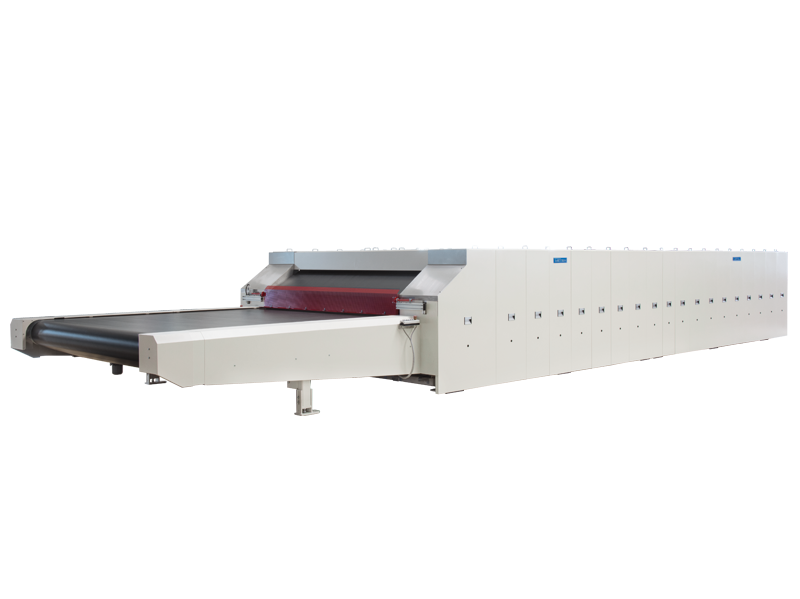

Skills in new dimensions

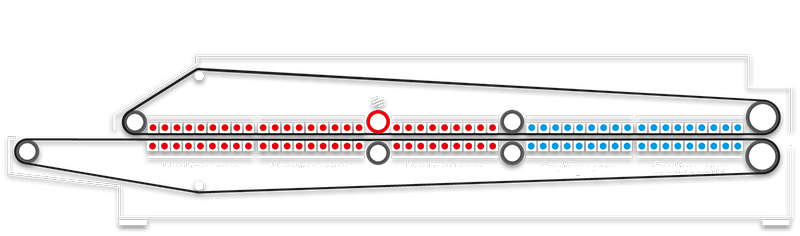

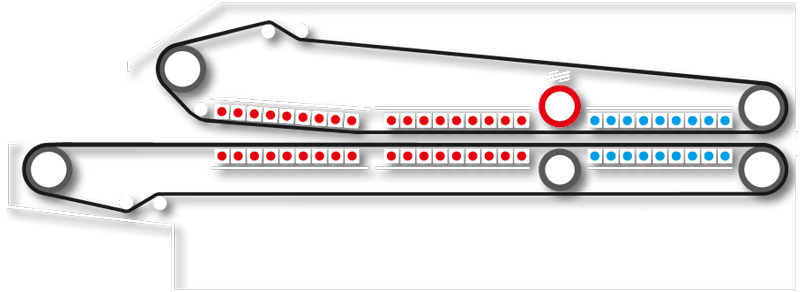

Designed in sturdy frame construction, we install separately spring-mounted elements, large roller diameters for precise pressure and combine chain guided, servo-driven conveyor belts.

We meet the increasing demands of long heating and cooling zones as well as large widths with large-sized drive rollers.

Belt‘s tension is generated either by means of springs or hydraulics. Belt control is carried out either by means of chain guidance or proportionally controlled belts.

Technical data

Width (mm) | 1,100 | 1,300 | 1,500 | 1,700 | 1,900 | 2,100 | 2,300 | 2,500 | 2,700 | 2,900 | 3,100 |

Height adjustment | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) |

Heating zone (mm) | 3,000, expandable in 1,500 mm steps | 3,000, expandable in 1,500 mm steps | 3,000, expandable in 1,500 mm steps | 3,000, expandable in 1,500 mm steps | 3,000, expandable in 1,500 mm steps | 3,000, expandable in 1,500 mm steps | 3,000, expandable in 1,500 mm steps | 3,000, expandable in 1,500 mm steps | 3,000, expandable in 1,500 mm steps | 3,000, expandable in 1,500 mm steps | 3,000, expandable in 1,500 mm steps |

Cooling zone (mm) | 1,500, expandable in 1,500 mm steps | 1,500, expandable in 1,500 mm steps | 1,500, expandable in 1,500 mm steps | 1,500, expandable in 1,500 mm steps | 1,500, expandable in 1,500 mm steps | 1,500, expandable in 1,500 mm steps | 1,500, expandable in 1,500 mm steps | 1,500, expandable in 1,500 mm steps | 1,500, expandable in 1,500 mm steps | 1,500, expandable in 1,500 mm steps | 1,500, expandable in 1,500 mm steps |

Control zones (number) | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 |

Running speed (m/min) | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 |

Versions |

Integrated heating and cooling zone / Only with heating zone / Only with cooling zone |

Integrated heating and cooling zone / Only with heating zone / Only with cooling zone |

Integrated heating and cooling zone / Only with heating zone / Only with cooling zone |

Integrated heating and cooling zone / Only with heating zone / Only with cooling zone |

Integrated heating and cooling zone / Only with heating zone / Only with cooling zone |

Integrated heating and cooling zone / Only with heating zone / Only with cooling zone |

Integrated heating and cooling zone / Only with heating zone / Only with cooling zone |

Integrated heating and cooling zone / Only with heating zone / Only with cooling zone |

Integrated heating and cooling zone / Only with heating zone / Only with cooling zone |

Integrated heating and cooling zone / Only with heating zone / Only with cooling zone |

Integrated heating and cooling zone / Only with heating zone / Only with cooling zone |

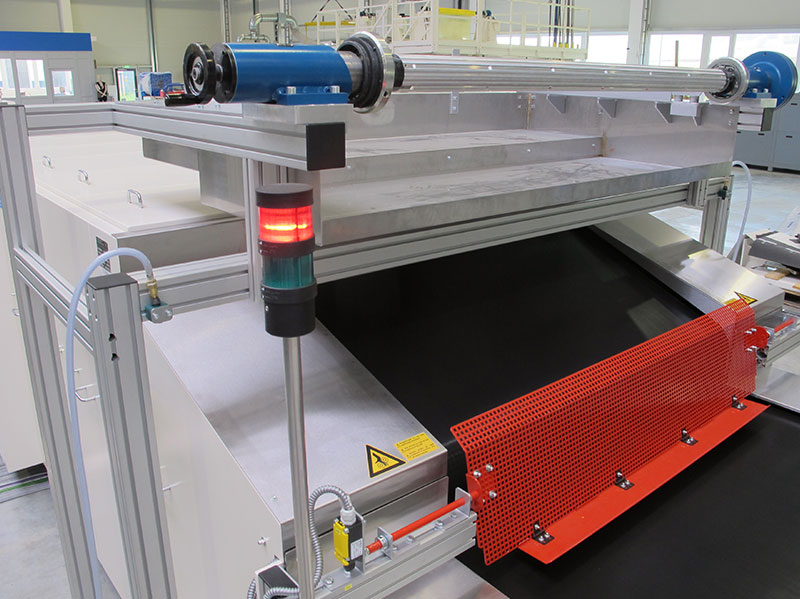

Flatbed laminating machine | Flatbed

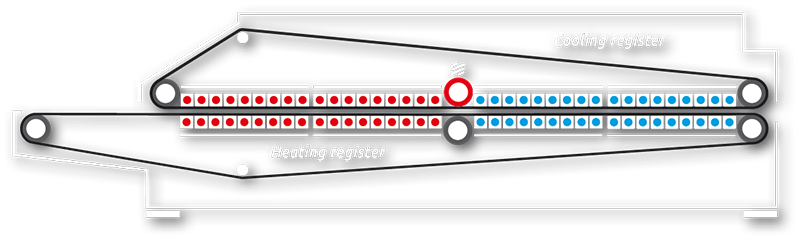

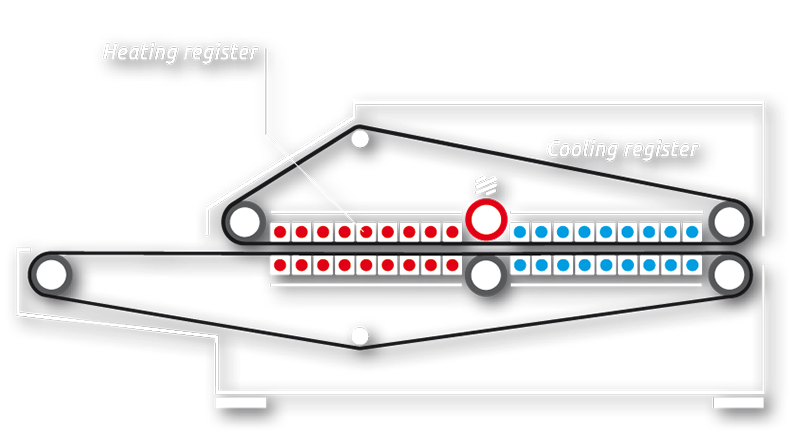

Heating and cooling in perfect balance

The combination of a reliable and powerful heating system with an effective cooling system allows processing of challenging materials with increased cooling demand.

The height adjustment as well as the level adjustment of the top pressure roller is motorcontrolled by means of a precisely adjustable lifting spindle. All relevant parameters can be set and controlled via proven SIEMENS touch control.

Technical data

Width (mm) | 1,100 | 1,300 | 1,500 | 1,700 | 1,900 | 2,100 | 2,300 | 2,500 | 2,700 |

Height adjustment | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) |

Heating zone (mm) | 2,300 | 2,300 | 2,300 | 2,300 | 2,300 | 2,300 | 2,300 | 2,300 | 2,300 |

Cooling zone (mm) | 2,300 | 2,300 | 2,300 | 2,300 | 2,300 | 2,300 | 2,300 | 2,300 | 2,300 |

Control zones (number) | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 |

Running speed (m/min) | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 |

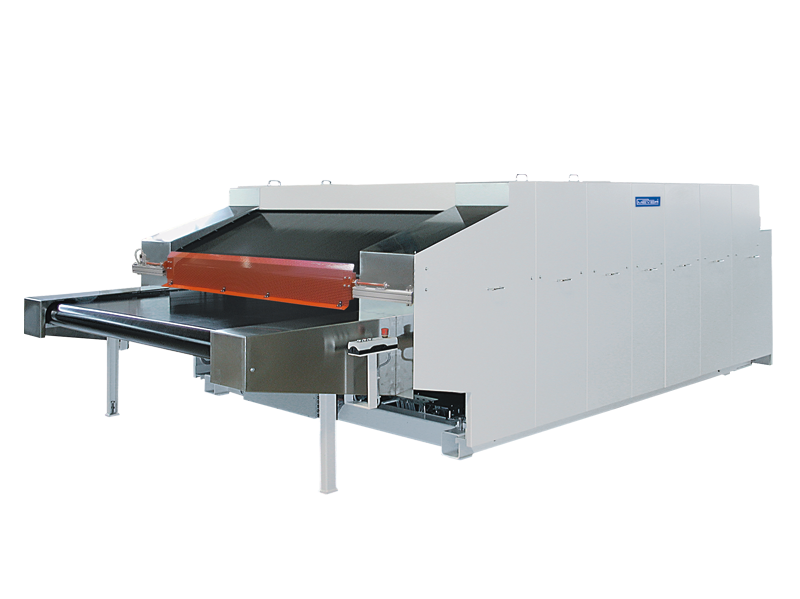

Flatbed laminating machine | Flatbed

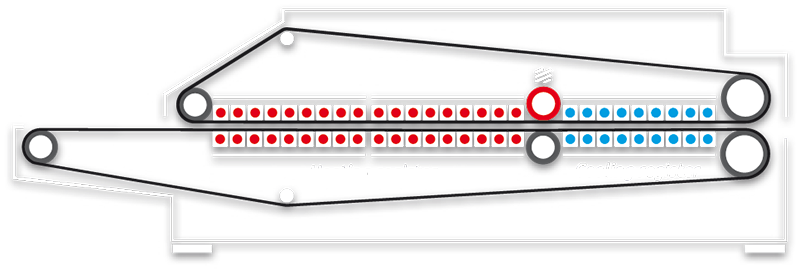

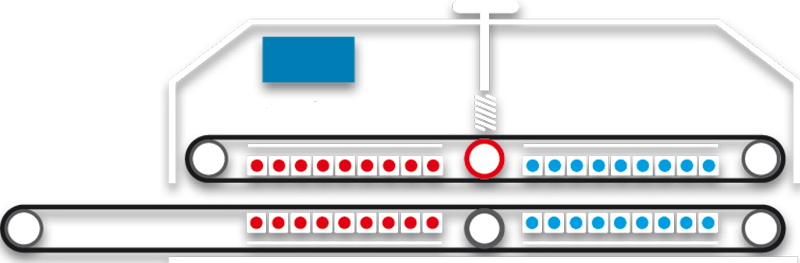

Higher energy input for increased demands

Designed in sturdy frame construction, we install separately spring-mounted elements, large roller diameters for precise pressure and combine chain guided, servo-driven conveyor belts. The reliable and powerful heating system can be designed in three different versions of heating capacities.

The 18 control zones are electrically heated. For optimal energy conservation, heating and cooling sections are insulated. The height adjustment as well as the level adjustment of the top pressure roller is motor-controlled by means of a precisely adjustable lifting spindle. All relevant parameters can be set and controlled via proven SIEMENS touch control.

Technical data

Width (mm) | 1,100 | 1,300 | 1,500 | 1,700 | 1,900 | 2,100 | 2,300 | 2,500 | 2,700 |

Height adjustment | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) |

Heating zone (mm) | 2,300 | 2,300 | 2,300 | 2,300 | 2,300 | 2,300 | 2,300 | 2,300 | 2,300 |

Cooling zone (mm) | 1,150 | 1,150 | 1,150 | 1,150 | 1,150 | 1,150 | 1,150 | 1,150 | 1,150 |

Control zones (number) | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 |

Running speed (m/min) | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 |

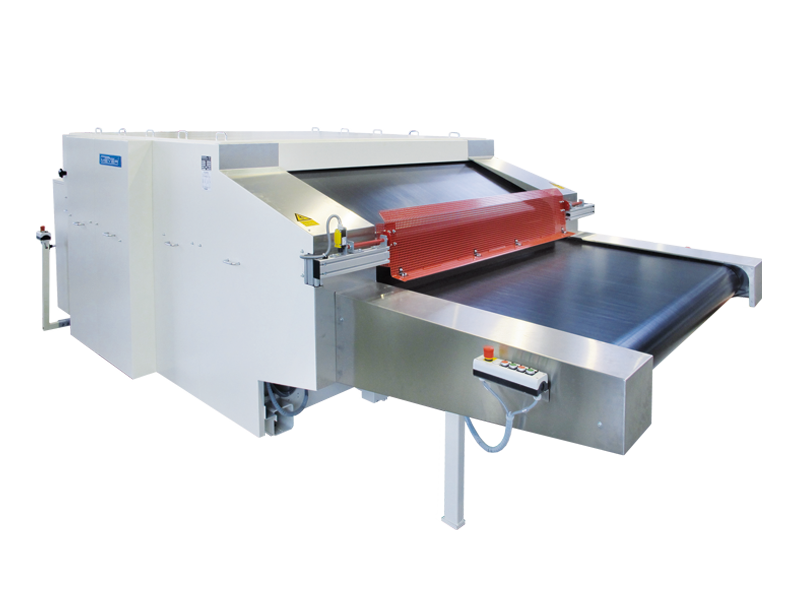

Flatbed laminating machine | Flatbed

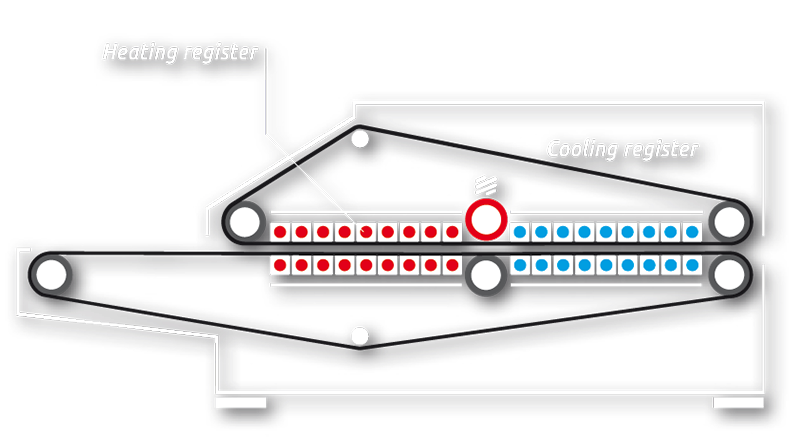

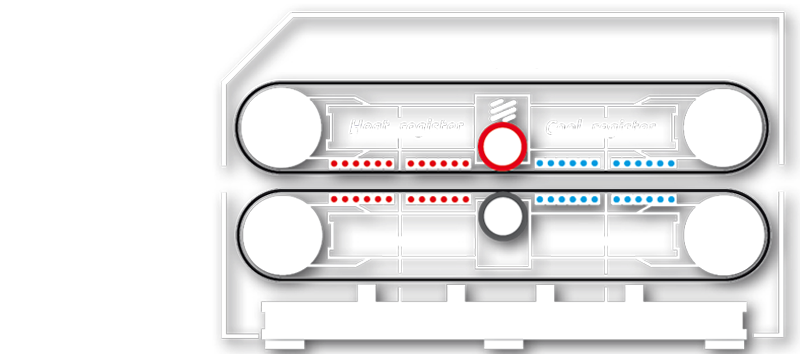

The solid solution for multi-purpose use

Designed in sturdy frame construction, we install separately spring-mounted elements, large roller diameters for precise pressure and combine chain guided, servo-driven conveyor belts. The height adjustment as well as level adjustments of the top pressure roller is motorcontrolled by means of a precisely adjustable lifting spindle. All relevant parameters can be set and controlled via proven SIEMENS touch control.

KFK-E Power

MEYER developed a special edition of the most successful Laminator KFK-E with some remarkable new features. The new KFK-E Power. More precision, more power, higher productivity and equipped with new belts for higher temperatures, while keeping a compact design.

Technical data

Width (mm) | 1,100 | 1,300 | 1,500 | 1,700 | 1,900 | 2,100 | 2,300 | 2,500 |

Height adjustment | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) |

Heating zone (mm) | 1,350 | 1,350 | 1,350 | 1,350 | 1,350 | 1,350 | 1,350 | 1,350 |

Cooling zone (mm) | 1,150 | 1,150 | 1,150 | 1,150 | 1,150 | 1,150 | 1,150 | 1,150 |

Control zones (number) | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 |

Running speed (m/min) | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 | 0.5 to 30 |

Flatbed laminating machine | Flatbed

Compact solutions with the skills of the Great

The system KFK-C is optimally suitable to laminate multilayer materials. Textiles, textile-like and flexible materials as well as rigid blanks with a thickness up to 50 mm can be processed without any difficulties.

As a result of an integrated cooling system, materials may also be coated. Furthermore, this machine is suitable to calibrate voluminous materials on account of the 4-fold height adjustment and adjustable calibration rollers. Adjustable sloped inlet.

The installation of endless belts is possible. The belts are proportionally tracked resulting in minimal cross movements.

Technical data

Width (mm) | 1,100 | 1,500 | 1,900 |

Height adjustment | 4-fold, 0 to 50 mm (1.96“) manual | 4-fold, 0 to 50 mm (1.96“) manual | 4-fold, 0 to 50 mm (1.96“) manual |

Heating zone Interval (mm) | 1,550 | 1,550 | 1,550 |

Cooling zone Interval (mm) | 980 | 980 | 980 |

Running speed (m/min) | 1 to 15 | 1 to 15 | 1 to 15 |

Versions |

Integrated heating and cooling zone Only with heating zone Only with cooling zone |

Integrated heating and cooling zone Only with heating zone Only with cooling zone |

Integrated heating and cooling zone Only with heating zone Only with cooling zone |

Flatbed laminating machine | Flatbed

The compact all-rounder with values of the big ones

The compact laminating machine is equipped with all finesse and fulfills highest demands for laboratory and research applications. It is also perfectly suitable for continuous production, works energy efficient and is built in solid and stable design.

Technical data

Width (mm) | 700 |

Height adjustment | 0 to 50 mm (1.96“) |

Heating zone (mm) | 750 |

Cooling zone (mm) | 550 |

Control zones (number) | 12 |

Running speed (m/min) | 0.2 to 12 |

Flatbed laminating machine | Flatbed

Small system solution – modular add-ons

We developed this laboratory laminating machine for smaller sizes as well as for manageable volumes. This stand-alone version represents a compact solution with one heating zone, equipped with separately spring-mounted elements and an integrated cooling zone.

The level of the pressure rollers as well as the pressure are individually manually adjustable. Steady guided conveyor belts and the intuitive operator guidance by means of the proven SIEMENS control represents new quality for laminating machines.

Technical data

Heating Zone (mm) | 520 | 520 |

Width (mm) | 400 | 600 |

Height adjustment | 0 to 25 mm (0.98“) | 0 to 25 mm (0.98“) |

Cooling zone (mm) | 360 | 360 |

Running speed (m/min) | 0.2 to 9 | 0.2 to 9 |

Laminating Machine | Flame

Flame lamination machine FKA

Soon you will find information about our flame laminating machine FKA here.

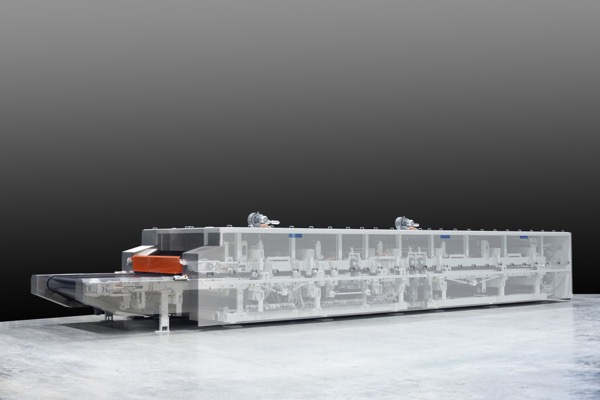

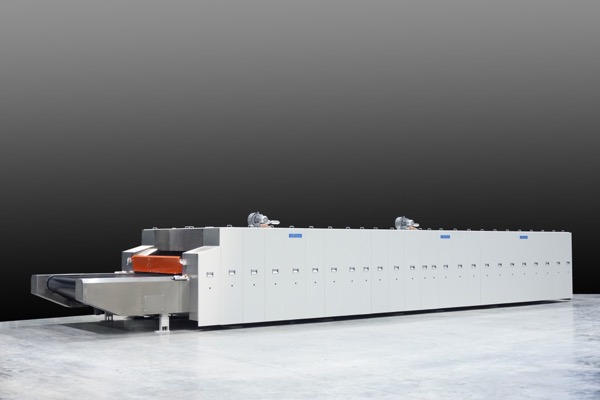

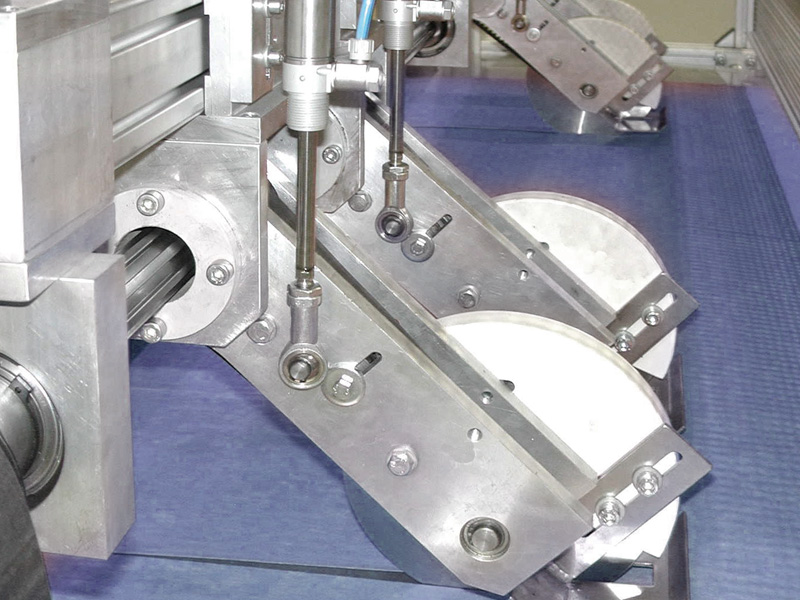

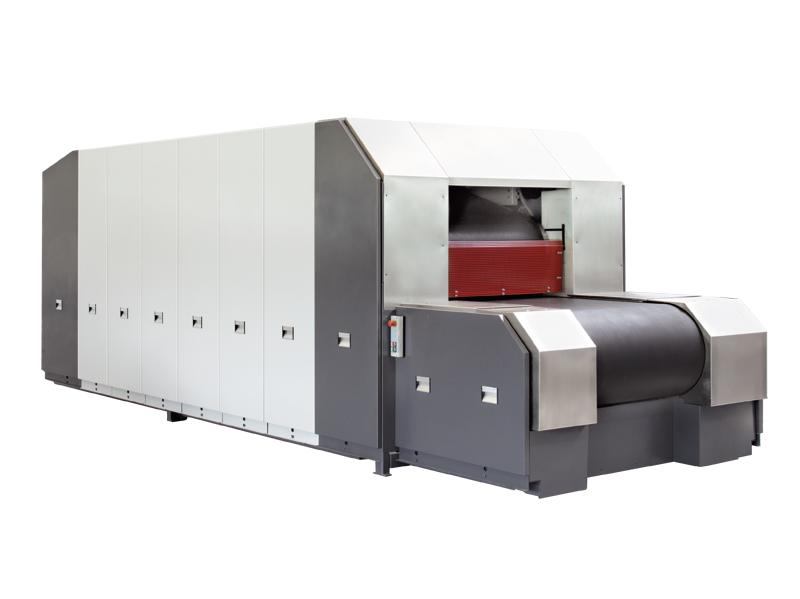

Hochdruck-Doppelbandpresse | High-pressure

Highest pressures at high temperatures

This precise system development represents the processing of organo sheets, fiber reinforced composites, and composites. Due to the consistent design for high pressures and high temperatures as well as the modular design, this is the economical alternative to the traditional steel belt lines.

Technical highlights are coated steel elements, hydraulic belt tension, hydraulically generated high pressure by means of pressure rollers, and pneumatic surface pressure onto the material to be laminated.

Technical data

Width (mm) | 1,100 | 1,500 | 1,900 |

Dimensions L x W x H (mm) | 6,300 x 2,600 x 2,350 | 6,300 x 3,000 x 2,350 | 6.300 x 3,400 x 2,350 |

Height adjustment | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) | 0 to 150 mm (5.90“) |

Total pressure max. (N/cm2) | 14.6 | 14.6 | 14.6 |

Pressure in all 4 zones max. (N/cm2) | 3.6 | 3.6 | 3.6 |

Pressure 800 mm zone max. (N/cm2) | 10 | 10 | 10 |

Surface pressure of rollers max. (N/cm2), rubber-coated | 260 (260) ** | 260 (260) ** | 170 (220) ** |

Line pressure of rollers max. (N/mm), rubber-coated | 70 (70) ** | 70 (70) ** | 37 (55) ** |

Temperature max. (°C) | 300 | 300 | 300 |

Heating power / module (kW) | 96 | 131 | 166 |

Length cooling module (mm) | 1,500, extendable in 1,500 mm modules | 1,500, extendable in 1,500 mm modules | 1,500, extendable in 1,500 mm modules |

Length heating module (mm) | 1,500, extendable in 1,500 mm modules | 1,500, extendable in 1,500 mm modules | 1,500, extendable in 1,500 mm modules |

Working width (mm) | 1,000 | 1,400 | 1,800 |

Weight approx. (kg) | 19,000 | 22,000 | 25,000 |

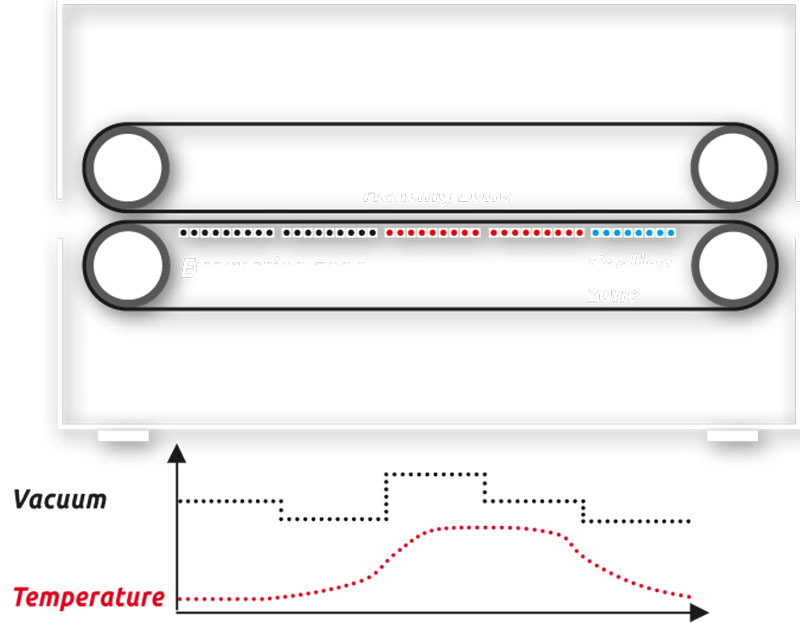

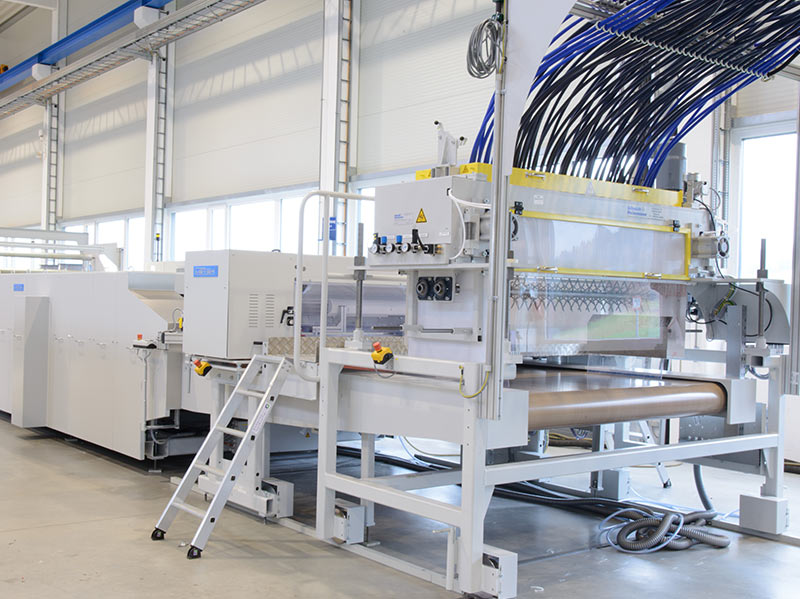

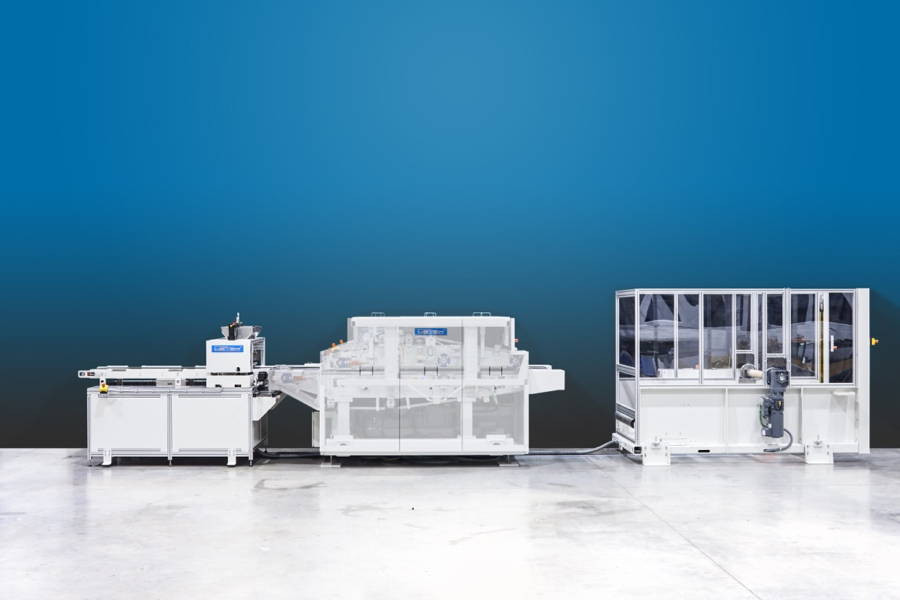

kontinuierliche Vakuum-Kaschiermaschine | Vacuum

The patented solutions for vacuum lamination

This special solution meets the high demands of a vacuum press, combined with the characteristics of a continuously working double-belt press with high zone pressures.

Flexible thin films, functional textiles or composites – even with height differences in the material to be laminated – are processed in each of the 5 zones under vacuum conditions avoiding air pockets in a continuous production process in an effective and energy-saving way.

Optimal laminating results ensure the zones, separately adjustable in vacuum and temperature, which are individually designed as heating or cooling zones depending on the specifications. Additionally, they can be equipped with IR heating elements.

Technical data

Working width (mm) | 800 |

Dimensions L x W x H (mm) | 5,000 x 2,500 x 1,700 |

Heating power (kW) | 170 |

Running speed (m/min) | 0.1 to 7 |

Thickness lamin. mat. max. (mm) | 5 |

Length of all zones (mm) | 4,000 |

Length / zone (mm) | 800 |

Pressure in all zones max. (bar) | 3.5 |

Pressure / zone max. (bar) | 0.8 |

Temperature max. (°C) | 250 |

Weight (kg) | 7,000 |